Everything in a Name...

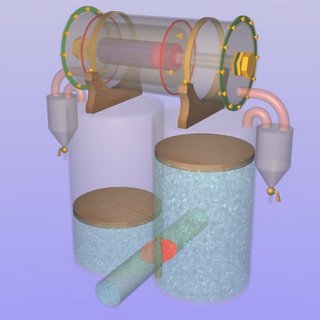

Yes, that's a marine diesel in the photo, a 1958 Baudouin straight-six of about 7 ½ litres called, predictably, "La Mère Baudouin" (Old Mother Baudouin), all the way from Marseilles. Indirect injection, 3000 kg without the gearbox, about 150 H.P. @ 950 rpm, air

start. She's the prime mover, nay, the very heart, of an old Douarnenez tunnyman which I lived and sailed aboard in 1998, and her unwavering beat rhythmed all our lives.

Naming things is fundamental to their form, and success. If you are called "Fred Bloggs' Typewriter Repair Emporium" you have little chance of being asked to do avant-garde shopfitting, signwriting, asked to repair key-cutting machines or saxophones... For this reason I have usually given my shops and workshops deliberately ambiguous names - in Eire the sign said "The Isoceles* Triangle, makers and menders", and we attracted the most amazing range of work. Naming is also important in the creation a "House", with its colours, fonts, little ways.

We had a nice workshop in Douarnenez, 400 m2 with a roller door and an inspection pit, that had been a "depôt de vins et spiritueux" and still smelled like it. We had a lot of fun, built Mardi Gras floats, windsurf boards, threw some momentous parties; friend SeB called it "Delta Zulu", after the town's call-letters DZ. Later I looked this up, and it means "Vessel (or aircraft) indicated appears to be in distress". Hmm.... mauvaise augure.

In graphics, and to a small degree in web design, I am known as Juliet_Hotel. This comes from an incident at Falmouth in '98. We had taken "Face au Vent" (that's her engine on the photo) from Douarnenez to Cornwall for the summer, and to the "Tall Ships" at Falmouth. Primped and painted, she was superbly appointed that year, and the welcome was wonderful, surely not what we would have seen aboard a yacht. Owner and crew were all retired eccentrics, and apart from a first-time-out butty I took with us, I was by far the youngest. Incorrigibles all; I had never seen 70-year-olds climbing poles to steal flags...

Steaming East into Falmouth at sun-up, about 04.00, I see a small open boat bearing down on us, or at least trying to, and throttle back.

- "Bonjooor" cries the young fellow, "How many are you aboard?"

"Seven!" I shout, and he then throws me across the waves the mother and father of all crabs, snapping and scuttling... I rush to kick the scuppers closed, so the hard-won beast doesn't return to his element, and then another, another... Seven huge crabs for breakfast! I never got that in a Dufour 11. Many Breton fishermen took refuge in Cornwall during the war to avoid the confiscation of their craft, and the ties are still strong. But I digress...

So, we arrive in the afternoon, having been specially invited for Falmouth is twinned with Douarnenez. We pick up a convenient buoy and call on 16, 09, 10, but to no avail. After half an hour the grey Coastguard MTB sweeps by, welcomes us, and hands us a little leaflet; we can stay on the buoy, at £15 a night, but as it's not theirs we might get moved at any time by the owner: anchoring is a mere £7.50, plus the probable cost of a diver to free the hook from the chains, cables and dead babies that litter the bottom in any harbour. Claude, the pasha, is outraged! "Quel accueil!" And it takes us two trips in

the rubber-duck to get ashore. After an evening on the town, where some of the sceptical crew discover for the first time the true merits of flat, tepid, turbid 9º ale from the wood, and Cornish Pasties...

Once more on board, Claude calls "Pare à lancer", "Je lance!"

He's the boss... and we pick our way in against a backdrop of bright lights, amongst the flotilla, to the town, where he has established that there is an old customs quay. Here we can dry out, secure between the wall and one of our "bequilles", which all Bréton boats carry. I put the boy down in the Zodiac, to take the lines, and off we go. This is perfect! We can come and go as we please, talk to the tourists, take on stores and water.

The quay, next to an ancient brick contraband-burning oven known as the "King's Tobacco Pipe", is just under the windows of the harbour-master's office. So, in true FaV stylie I run up the signal

"Juliet Hotel" - "I am aground. I am in no danger." at the crosstrees. As there was no price on the none-too-welcoming leaflet for being run aground, we had nothing to pay. Now, since I have become a bit too old to run up the ratlines with a belaying pin between my teeth, I find this name appropriate.

*Spot the (deliberate) mistake. Two people noticed this in about seven

years, but then I suppose it's a bit subtle, or perhaps they were too

polite to mention it...

Isosceles - from the Greek; Iso; the same, and Skelos; a leg.

Isoceles - with Iso and, from Latin, caeles; skies, heavens.

Thus, an association not of people with two legs both the same, but of

those with the same dream. A wee bit obscure amongst a population many

of whom contented themselves with a vocabulary of 600 words... But I

liked it.